Can You Take 1900 s Clear Glass That Is Darkened and Make It Clear Again

The history of glass-making dates dorsum to at least 3,600 years ago in Mesopotamia. However, some writers claim that they may accept been producing copies of drinking glass objects from Arab republic of egypt.[1] Other archaeological show suggests that the first true drinking glass was made in littoral north Syria, Mesopotamia or Egypt.[2] The earliest known glass objects, of the mid 2,000 BCE, were beads, peradventure initially created equally the accidental past-products of metal-working (slags) or during the production of faience, a pre-glass vitreous material made by a procedure similar to glazing.[n one] Glass products remained a luxury until the disasters that overtook the tardily Bronze Historic period civilizations seemingly brought glass-making to a halt.

Development of glass technology in India may have begun in 1,730 BCE.[three] In Ancient China, glass-making had a afterward get-go compared to ceramics and metallic work.

From across the old Roman Empire, archaeologists have recovered glass objects that were used in domestic, industrial and funerary contexts. Anglo-Saxon glass has been found across England during archaeological excavations of both settlement and cemetery sites. Glass in the Anglo-Saxon menses was used in the manufacture of a range of objects, including vessels, beads, windows, and was even used in jewelry.

Origins [edit]

Naturally occurring glass, especially the volcanic glass obsidian, has been used by many Rock Age societies across the globe for the production of sharp cut tools and, due to its limited source areas, was extensively traded. But in general, archaeological show suggests that the showtime true drinking glass was made in coastal north Syria, Mesopotamia or ancient Egypt.[2] Considering of Egypt's favorable environment for preservation, the bulk of well-studied early glass is institute there, although some of this is likely to have been imported. The primeval known drinking glass objects, of the mid-tertiary millennium BCE, were beads, perhaps initially created as accidental by-products of metal-working (slags) or during the product of faience, a pre-glass vitreous material made by a process like to glazing.[due north i]

During the Late Bronze Age in Egypt (e.g., the Ahhotep "Treasure") and Western Asia (e.g., Megiddo),[4] there was a rapid growth in glassmaking engineering science. Archaeological finds from this menstruum include colored glass ingots, vessels (often colored and shaped in imitation of highly prized hardstone carvings in semi-precious stones) and the ubiquitous beads. The alkali of Syrian and Egyptian drinking glass was soda ash (sodium carbonate), which can exist extracted from the ashes of many plants, notably halophile seashore plants like saltwort. The latest vessels were 'cadre-formed', produced by winding a ductile rope of glass around a shaped core of sand and dirt over a metal rod, then fusing it by reheating information technology several times.[ citation needed ]

Threads of thin glass of unlike colors made with admixtures of oxides were later on wound around these to create patterns, which could be drawn into festoons past using metal raking tools. The vessel would then be rolled smooth (marvered) on a slab in order to printing the decorative threads into its body. Handles and anxiety were applied separately. The rod was subsequently immune to cool as the glass slowly annealed and was eventually removed from the centre of the vessel, after which the core material was scraped out. Drinking glass shapes for inlays were also often created in moulds. Much of early glass product, notwithstanding, relied on grinding techniques borrowed from rock working. This meant that the glass was ground and carved in a cold state.[five]

By the 15th century BCE, extensive glass production was occurring in Western asia, Crete, and Arab republic of egypt; and the Mycenaean Greek term 𐀓𐀷𐀜𐀺𐀒𐀂 , ku-wa-no-wo-ko-i, meaning "workers of lapis lazuli and glass" (written in Linear b syllabic script) is attested.[6] [vii] [eight] [n 2] [north iii] It is thought that the techniques and recipes required for the initial fusing of glass from raw materials were a closely guarded technological hush-hush reserved for the large palace industries of powerful states. Glass workers in other areas therefore relied on imports of preformed glass, often in the class of cast ingots such equally those found on the Ulu Burun shipwreck off the coast of modern Turkey.[ citation needed ]

An early 18th-century goblet with coats of artillery in the District Museum in Tarnów is one of the highest (54.3 cm, 21.4 in) preserved examples of artistry of less known Lubaczów glass manufacturing factory.[xi] The goblet was almost entirely covered with a pattern of and then-called carp scales and paw-engraved decoration.[eleven]

Glass remained a luxury cloth, and the disasters that overtook Belatedly Statuary Age civilizations seemed to have brought drinking glass-making to a halt.[ citation needed ] It picked up again in its sometime sites, Syrian arab republic and Republic of cyprus, in the 9th century BCE, when the techniques for making colorless drinking glass were discovered.[ citation needed ]

The first glassmaking "transmission" dates dorsum to ca. 650 BCE. Instructions on how to make glass are independent in cuneiform tablets discovered in the library of the Assyrian rex Ashurbanipal.[ citation needed ]

In Egypt, glass-making did not revive until it was reintroduced in Ptolemaic Alexandria. Cadre-formed vessels and beads were yet widely produced, but other techniques came to the fore with experimentation and technological advancements.[ citation needed ]

During the Hellenistic menstruum many new techniques of glass production were introduced and glass began to be used to brand larger pieces, notably table wares. Techniques adult during this period include 'slumping' viscous (just not fully molten) drinking glass over a mould in order to form a dish and 'millefiori' (meaning 'grand flowers') technique, where canes of multicolored drinking glass were sliced and the slices arranged together and fused in a mould to create a mosaic-similar effect. Information technology was also during this menses that colorless or decolored glass began to be prized and methods for achieving this effect were investigated more than fully.[12]

According to Pliny the Elderberry, Phoenician traders were the beginning to stumble upon drinking glass manufacturing techniques at the site of the Belus River. Georgius Agricola, in De re metallica, reported a traditional serendipitous "discovery" tale of familiar blazon:

"The tradition is that a merchant ship laden with nitrum being moored at this identify, the merchants were preparing their repast on the embankment, and not having stones to prop upward their pots, they used lumps of nitrum from the ship, which fused and mixed with the sands of the shore, and at that place flowed streams of a new translucent liquid, and thus was the origin of glass."[13]

This account is more a reflection of Roman experience of glass product, still, as white silica sand from this surface area was used in the production of glass within the Roman Empire due to its loftier purity levels. During the 1st century BCE, glass blowing was discovered on the Syro-Judean coast, revolutionizing the industry. Drinking glass vessels were now cheap compared to pottery vessels. Growth of the use of drinking glass products occurred throughout the Roman world.[ citation needed ] Glass became the Roman plastic, and glass containers produced in Alexandria[ commendation needed ] spread throughout the Roman Empire. With the discovery of clear glass (through the introduction of manganese dioxide), by drinking glass blowers in Alexandria circa 100 AD, the Romans began to utilize drinking glass for architectural purposes. Cast glass windows, albeit with poor optical qualities, began to appear in the most of import buildings in Rome and the virtually luxurious villas of Herculaneum and Pompeii. Over the adjacent one,000 years, glass making and working connected and spread through southern Europe and across.[ citation needed ]

History by culture [edit]

Iran [edit]

The commencement Persian glass comes in the form of beads dating to the late Bronze Age (1600 BCE), and was discovered during the explorations of Dinkhah Tepe in Iranian Azerbaijan past Charles Burney. Glass tubes were discovered past French archaeologists at Chogha Zanbil, belonging to the middle Elamite menses. Mosaic glass cups have also been establish at Teppe Hasanlu and Marlik Tepe in northern Islamic republic of iran, dating to the Iron Age. These cups resembles ones from Mesopotamia, equally do cups found in Susa during the late Elamite flow.

Glass tubes containing kohl accept also been found in Iranian Azerbaijan and Kurdistan Province, belonging to the Achaemenid flow. During this time, glass vessels were usually plain and colorless. By the Seleucid and tardily Parthian era, Greek and Roman techniques were prevalent. During the Sasanian menstruation, drinking glass vessels were decorated with local motifs.[fourteen]

Republic of india [edit]

Bear witness of glass during the chalcolithic has been found in Hastinapur, India.[15] The earliest glass detail from the Indus Valley Culture is a brown glass bead institute at Harappa, dating to 1700 BCE. This makes it the earliest testify of glass in South asia.[3] [xvi] Drinking glass discovered from later sites dating from 600 to 300 BEC displays common colors.[3]

Texts such as the Shatapatha Brahmana and Vinaya Pitaka mention glass, implying they could accept been known in India during the early first millennium BCE.[15] Glass objects take also been establish at Beed, Sirkap and Sirsukh, all dating to around the 5th century BCE.[17] Even so, the start unmistakable testify for widespread glass usage comes from the ruins of Taxila (3rd century BEC), where bangles, beads, small-scale vessels, and tiles were discovered in big quantities.[15] These glassmaking techniques may accept been transmitted from cultures in Western Asia.[17]

The site of Kopia, in Uttar Pradesh, is the first site in India to locally industry drinking glass, with items dating between the 7th century BCE to the 2nd century ce.[18] Early Indian glass of this period was probable fabricated locally, as they differ significantly in chemical composition when compared to Babylonian, Roman and Chinese glass.[17]

Past the 1st century AD, glass was being used for ornaments and casing in Southern asia.[15] Contact with the Greco-Roman globe added newer techniques, and Indians artisans mastered several techniques of drinking glass molding, decorating and coloring by the succeeding centuries.[xv] The Satavahana catamenia of Republic of india also produced brusque cylinders of blended glass, including those displaying a lemon yellow matrix covered with green glass.[19]

China [edit]

In China, glass played a peripheral function in arts and crafts when compared to ceramics and metallic work.[20] The primeval glass items in Prc come from the Warring States period (475–221 BCE), although they are rare in number and express in archaeological distribution.

Glassmaking developed subsequently in Prc compared to cultures in Mesopotamia, Egypt and India.[21] Imported drinking glass objects start reached Prc during the late Spring and Autumn period (early on 5th century BCE), in the form of polychrome eye beads.[22] These imports created the impetus for the production of ethnic glass beads.

During the Han Dynasty (206 BCE–220 CE), the utilise of drinking glass diversified. The introduction of glass casting in this catamenia encouraged the production of moulded objects, such every bit bi disks and other ritual objects.[21] Chinese glass objects from the Warring States and Han menstruum vary profoundly in chemical composition from the imported drinking glass objects. The glasses from this period contain high levels of barium oxide and lead, distinguishing them from the soda-lime-silica glasses of Western Asia and Mesopotamia.[23] At the end of the Han Dynasty (AD 220), the atomic number 82-barium drinking glass tradition declined, with glass production simply resuming during the fourth and 5th centuries Advertizement.[24] Literary sources also mention the manufacture of drinking glass during the 5th century Advert.[25]

Romans [edit]

Roman glass production developed from Hellenistic technical traditions, initially concentrating on the production of intensely colored, cast drinking glass vessels. Drinking glass objects have been recovered across the Roman Empire[26] in domestic, funerary[27] and industrial contexts.[28] Glass was used primarily for the production of vessels, although mosaic tiles and window glass were also produced.

Yet, during the 1st century AD, the manufacture underwent rapid technical growth that saw the introduction of glass-blowing and the dominance of colorless or 'aqua' glasses. Raw glass was produced in geographically separate locations to the working of glass into finished vessels,[29] [thirty] and, past the terminate of the 1st century CE, large scale manufacturing, primarily in Alexandria,[31] resulted in the establishment of drinking glass as a commonly available fabric in the Roman globe.

Islamic earth [edit]

Islamic drinking glass continued the achievements of pre-Islamic cultures, especially the Sasanian glass of Persia. The Arab poet al-Buhturi (820–897) described the clarity of such drinking glass: "Its colour hides the glass as if information technology is continuing in information technology without a container."[32] In the 8th century, the Farsi-Arab chemist Jābir ibn Hayyān (Geber) described 46 recipes for producing colored glass in Kitab al-Durra al-Maknuna (The Book of the Subconscious Pearl), in addition to 12 recipes inserted by al-Marrakishi in a later edition of the book.[33] By the 11th century, clear glass mirrors were being produced in Islamic Spain.[ commendation needed ]

Africa [edit]

During post-classical times, glass and glass beads were also produced in the kingdom of Benin.[34]

Medieval Europe [edit]

A 16th-century stained drinking glass window

Afterwards the collapse of the Western Roman Empire, independent glass making technologies emerged in Northern Europe, with artisan forest drinking glass produced by several cultures. Byzantine Glass evolved the Roman tradition, in the Eastern Empire. The hook beaker was pop equally a relatively easy to brand but an impressive vessel that exploited the unique potential of drinking glass.[ citation needed ]

Glass objects from the 7th and 8th centuries take been plant on the isle of Torcello well-nigh Venice. These form an important link between Roman times and the afterward importance of that metropolis in the production of the fabric. Effectually 1000 AD, an of import technical breakthrough was made in Northern Europe when soda glass, produced from white pebbles and burnt vegetation was replaced past glass made from a much more readily available material: potash obtained from woods ashes. From this point on, northern glass differed significantly from that made in the Mediterranean surface area, where soda remained in common employ.[35]

Until the 12th century, stained glass – drinking glass to which metallic or other impurities had been added for coloring – was not widely used, but information technology apace became an important medium for Romanesque art and especially Gothic art. Almost all survivals are in church building buildings, only it was also used in one thousand secular buildings. The 11th century saw the emergence in Deutschland of new ways of making sheet glass past blowing spheres. The spheres were swung out to form cylinders and and so cut while nevertheless hot, afterwards which the sheets were flattened. This technique was perfected in 13th century Venice. The crown glass process was used up to the mid-19th century. In this process, the glassblower would spin approximately 9 pounds (4 kg) of molten glass at the end of a rod until it flattened into a disk approximately v anxiety (1.v m) in diameter. The disk would then be cut into panes. Domestic drinking glass vessels in late medieval Northern Europe are known as forest glass.[ commendation needed ]

Anglo-Saxon world [edit]

Anglo-Saxon glass has been constitute beyond England during archaeological excavations of both settlement and cemetery sites. Drinking glass in the Anglo-Saxon period was used in the manufacture of a range of objects including vessels, beads, windows and was even used in jewelry.[36] In the 5th century Advertizing with the Roman difference from Britain, in that location were also considerable changes in the usage of glass.[37] Excavation of Romano-British sites has revealed plentiful amounts of drinking glass only, in contrast, the amount recovered from the fifth century and later Anglo-Saxon sites is minuscule.[37]

The majority of complete vessels and assemblages of beads come from the excavations of early on Anglo-Saxon cemeteries, only a change in burial rites in the late 7th century afflicted the recovery of glass, as Christian Anglo-Saxons were buried with fewer grave appurtenances, and glass is rarely establish. From the tardily 7th century onwards, window glass is found more frequently. This is directly related to the introduction of Christianity and the construction of churches and monasteries.[37] [38] There are a few Anglo-Saxon ecclesiastical[39] literary sources that mention the production and employ of drinking glass, although these relate to window glass used in ecclesiastical buildings.[37] [38] [xl] Glass was besides used by the Anglo-Saxons in their jewelry, both as enamel or as cut glass insets.[41] [42]

Murano [edit]

The center for luxury Italian glassmaking from the 14th century was the isle of Murano, which developed many new techniques and became the center of a lucrative export merchandise in dinnerware, mirrors, and other items. What fabricated Venetian Murano glass significantly dissimilar was that the local quartz pebbles were nigh pure silica, and were ground into a fine clear sand that was combined with soda ash obtained from the Levant, for which the Venetians held the sole monopoly. The clearest and finest glass is tinted in two ways: firstly, a natural coloring agent is footing and melted with the glass. Many of these coloring agents all the same exist today; for a list of coloring agents, come across below. Blackness glass was called obsidianus afterwards obsidian stone. A 2nd method is apparently to produce a blackness drinking glass which, when held to the low-cal, volition show the true color that this glass will give to another glass when used as a dye.[43]

The Venetian ability to produce this superior form of glass resulted in a trade advantage over other glass producing lands. Murano's reputation as a center for glassmaking was built-in when the Venetian Democracy, fearing burn might fire the city's mostly wood buildings, ordered glassmakers to move their foundries to Murano in 1291.[ citation needed ] Murano's glassmakers were soon the island's most prominent citizens. Glassmakers were non allowed to exit the Republic. Many took a hazard and set up glass furnaces in surrounding cities and equally far afield as England and holland.[ commendation needed ]

Bohemia [edit]

Bohemian drinking glass, or Bohemia crystal, is a decorative glass produced in regions of Bohemia and Silesia, at present in the current state of the Czech republic, since the 13th century.[44] Oldest archeology excavations of glass-making sites date to around 1250 and are located in the Lusatian Mountains of Northern Bohemia. Most notable sites of drinking glass-making throughout the ages are Skalice (German: Langenau), Kamenický Šenov (German: Steinschönau) and Nový Bor (German: Haida). Both Nový Bor and Kamenický Šenov have their ain Drinking glass Museums with many items dating since effectually 1600. It was especially outstanding in its manufacture of glass in high Bizarre manner from 1685 to 1750. In the 17th century, Caspar Lehmann, gem cutter to Emperor Rudolf II in Prague, adapted to glass the technique of gem engraving with copper and bronze wheels.[ commendation needed ]

Modernistic glass product [edit]

New processes [edit]

Glassblowers at work. Retort making.

A very important advance in drinking glass manufacture was the technique of adding pb oxide to the molten glass; this improved the appearance of the glass and made it easier to melt using sea-coal as a furnace fuel. This technique likewise increased the "working menstruum" of the glass, making it easier to manipulate. The process was first discovered by George Ravenscroft in 1674, who was the first to produce clear atomic number 82 crystal glassware on an industrial scale. Ravenscroft had the cultural and financial resource necessary to revolutionise the glass trade, allowing England to overtake Venice every bit the heart of the glass industry in the eighteenth and nineteenth centuries. Seeking to notice an culling to Venetian cristallo, he used flint as a silica source, but his glasses tended to crizzle, developing a network of small cracks destroying its transparency. This was eventually overcome by replacing some of the potash flux with lead oxide to the melt.[45]

He was granted a protective patent in where production and refinement moved from his glasshouse on the Savoy to the seclusion of Henley-on-Thames.[46]

By 1696, subsequently the patent expired, 20-seven glasshouses in England were producing flint glass and were exporting all over Europe with such success that, in 1746, the British Authorities imposed a lucrative tax on it. Rather than drastically reduce the lead content of their glass, manufacturers responded by creating highly decorated, smaller, more delicate forms, oft with hollow stems, known to collectors today as Excise glasses.[47] The British drinking glass making industry was able to take off with the repeal of the taxation in 1845.

Evidence of the use of the diddled plate glass method dates dorsum to 1620 in London and was used for mirrors and coach plates. Louis Lucas de Nehou and A. Thevart perfected the process of casting Polished plate drinking glass in 1688 in France. Prior to this invention, mirror plates, made from blown "sheet" glass, had been limited in size. De Nehou'due south procedure of rolling molten glass poured on an iron table rendered the manufacture of very large plates possible.[48] This method of production was adopted by the English in 1773 at Ravenhead. The polishing process was industrialized effectually 1800 with the adoption of a steam engine to behave out the grinding and polishing of the cast glass.

Industrial product [edit]

The façade of the Crystal Palace, one of the starting time buildings to use drinking glass as the principal fabric for structure.

The use of glass as a building material was heralded by The Crystal Palace of 1851, congenital by Joseph Paxton to business firm the Groovy Exhibition. Paxton's revolutionary new building inspired the public apply of glass as a material for domestic and horticultural compages. In 1832, the British Crown Glass Company (later Adventure Brothers) became the beginning company to adopt the cylinder method to produce canvas glass with the expertise of Georges Bontemps, a famous French glassmaker.[n 4] This drinking glass was produced past blowing long cylinders of drinking glass, which were then cut along the length and and then flattened onto a cast-iron table, before being annealed. Plate drinking glass involves the glass beingness ladled onto a bandage-atomic number 26 bed, where information technology is rolled into a sheet with an atomic number 26 roller. The sail, still soft, is pushed into the open mouth of an annealing tunnel or temperature-controlled oven called a lehr, downwardly which information technology was carried by a system of rollers.[49] James Hartley introduced the Rolled Plate method in 1847. This allowed a ribbed end and was often used for extensive glass roofs such equally within railway stations.

An early on advance in automating glass manufacturing was patented in 1848 by the engineer Henry Bessemer. His system produced a continuous ribbon of flat glass by forming the ribbon between rollers. This was an expensive process, every bit the surfaces of the drinking glass needed polishing and was later on abandoned past its sponsor, Robert Lucas Run a risk of Chance Brothers, as unviable. Bessemer also introduced an early on form of "Float Glass" in 1843, which involved pouring glass onto liquid tin.

In 1887, the mass production of glass was adult by the firm Ashley in Castleford, Yorkshire. This semi-automatic process used machines that were capable of producing 200 standardized bottles per hour, many times quicker than the traditional methods of manufacture.[50] Chance Brothers too introduced the machine rolled patterned glass method in 1888.[51]

In 1898, Pilkington invented Wired Cast drinking glass, where the glass incorporates a potent steel-wire mesh for safe and security. This was commonly given the misnomer "Georgian Wired Drinking glass" but it greatly post-dates the Georgian era.[52] The Machine Drawn Cylinder technique was invented in the US and was the first mechanical method for the drawing of window drinking glass. Information technology was manufactured under licence in the Uk by Pilkington from 1910 onwards.

In 1938, the polished plate procedure was improved by Pilkington which incorporated a double grinding process to give an improved quality to the stop. Between 1953 and 1957, Sir Alastair Pilkington and Kenneth Bickerstaff of the Uk's Pilkington Brothers adult the revolutionary bladder drinking glass process, the first successful commercial application for forming a continuous ribbon of glass using a molten tin bathroom on which the molten drinking glass flows unhindered under the influence of gravity.[53] This method gave the sheet uniform thickness and very apartment surfaces. Modern windows are made from float glass. Virtually float drinking glass is soda-lime glass, simply relatively pocket-sized quantities of specialty borosilicate[54] and flat panel display glass are also produced using the bladder drinking glass process. The success of this procedure lay in the careful balance of the volume of drinking glass fed onto the bath, where it was flattened past its own weight.[55] Full scale assisting sales of float glass were first achieved in 1960.

Gallery [edit]

-

Phoenician drinking glass necklace 5th–6th century BC

-

Roman glass amphoriskoi 1st–2nd century AD

-

Blue head flask (Roman, Advertizement 300–500, bandage drinking glass)

-

Lombardic glass drinking horn 6th–seventh century AD

-

Two cups cobalt blue drinking glass with aureate floral decoration from India, Mughal, circa 1700–1775

-

Base for a h2o pipe, Republic of india, Mughal, c. 1700–1775

-

Venetian goblet made in Italia in the early 19th century

-

Bracelets with peacocks, Delhi, enameled silver inlaid with gemstones and glass, 19th century

-

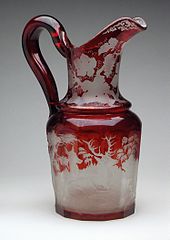

Jug, 1876, James Powell & Sons

-

Siphon bottle for seltzer h2o, 1922

-

New Martinsville Glass Hostmaster Tea Cup, cobalt blue, 1930

See also [edit]

- Early glassmaking in the United states of america

Notes [edit]

- ^ a b True glazing over a ceramic body was non used until many centuries subsequently the production of the first glass.

- ^ Plant on the MY Oi 701, MY Oi 702, MY Oi 703 and MY Oi 704 tablets; the least damaged, as far every bit this give-and-take is concerned, is MY Oi 703.[9]

- ^ Cf. κύανος .[ten]

- ^ This procedure was used extensively until early on in the 20th Century to make window glass.

References [edit]

- ^ "Drinking glass making may have begun in Egypt, not Mesopotamia Artifacts from Iraq site show less sophisticated technique, colour palette". 2016-eleven-22. Retrieved 2016-11-25 .

- ^ a b "Drinking glass Online: The History of Glass". Archived from the original on Apr fifteen, 2011. Retrieved 2007-10-29 .

- ^ a b c Gowlett, J.A.J. (1997). High Definition Archæology: Threads Through the By. Routledge. ISBN0-415-18429-0.

- ^ These early examples are drawn from Christine Lilyquist (1993). "Granulation and Glass: Chronological and Stylistic Investigations at Selected Sites, ca. 2500-1400 B.C.E.". Bulletin of the American Schools of Oriental Research. 290/291 (290): 29–94. doi:x.2307/1357319. JSTOR 1357319. S2CID 163645343.

- ^ Wilde, H. "Technologische Innovationen im two. Jahrtausend v. Chr. Zur Verwendung und Verbreitung neuer Werkstoffe im ostmediterranen Raum". GOF IV, Bd 44, Wiesbaden 2003, 25–26.

- ^ "The Linear B word ku-wa-no-wo-ko". Palaeolexicon. Give-and-take study tool for ancient languages.

- ^ Wilde, H. "Technologische Innovationen im ii. Jahrtausend v. Chr. Zur Verwendung und Verbreitung neuer Werkstoffe im ostmediterranen Raum". GOF Iv, Bd 44, Wiesbaden 2003, 25–26 ISBN 3-447-04781-X

- ^ McCray, W. Patrick (2007) Prehistory and history of glassmaking engineering, American Ceramic Society, ISBN ane-57498-041-six

- ^ "MY Oi 701 (63)". "MY Oi 702 (64)". "MY Oi 703 (64)". "MY Oi 704 (64)". "Database of Mycenaean at Oslo DĀMOS: publisher: Academy of Oslo".

- ^ κύανος . Liddell, Henry George; Scott, Robert; A Greek–English Lexicon at the Perseus Project.

- ^ a b "Kielich (flet) z herbami "Pogoń" i "Szreniawa"". muzea.malopolska.pl (in Polish). Retrieved 7 July 2014.

- ^ Douglas, R. W. (1972). A history of glassmaking. Henley-on-Thames: One thousand T Foulis & Co Ltd. ISBN0-85429-117-2.

- ^ Agricola, Georgius, De re metallica, translated by Herbert Clark Hoover and Lou Henry Hoover, Dover Publishing. De Re Metallica Trans. by Hoover Online Version Page 586. Retrieved September 12, 2007

- ^ Ṣāliḥʹvand, Navīd (2015). Tārīkhchah-i shīshah va shīshahʹgarī : ẓurūf-i shīshahʹī dawrah-i Ashkānī, majmūʻah-i Mūzih-i Millī va Mūzih-i Riz̤ā ʻAbbāsī [The history of drinking glass and drinking glass making : drinking glass vessels of Arsacid era in the collections of Islamic republic of iran National Museum and Reza Abbasi Museum] (in Persian) (Chāp-i avval ed.). [Tihrān]: Samīrā. ISBN9789648955491. OCLC 933388489.

- ^ a b c d due east Ghosh, Amalananda (1990). An Encyclopaedia of Indian Archaeology. BRILL. ISBNninety-04-09262-five.

- ^ "The Aboriginal Indus Valley" (PDF).

- ^ a b c D.G., Bose, ed. (1971). A Concise History of Science in Bharat. Indian National Science University. p. xv. ISBN8173716196.

- ^ Kanungo, Alok K.; Brill, Robert H. (January 2009). "Kopia, India's First Glassmaking Site: Dating and Chemical Assay". Journal of Glass Studies. 51: 11–25.

- ^ Ghosh, Amalananda (1990). "Ornaments, Gems etc. (Ch. 10)". An Encyclopaedia of Indian Archaeology. BRILL. ISBNninety-04-09262-5.

- ^ Braghin, C. (2002) "Introduction" pp. XI-XIV in Braghin, C. (ed) Chinese Glass. Archaeological studies on the uses and social competition of glass artefacts from the Warring States to the Northern Vocal Menses (5th century B.C. to twelfth century A.D.). ISBN 8822251628.

- ^ a b Pinder-Wilson, R. (1991) "The Islamic lands and China" p. 140 in Tait, H. (ed) Five thousand years of glass. University of Pennsylvania Press.

- ^ Braghin, C. (2002) "Polychrome and monochrome glass of the Warring States and Han periods" p. vi in Braghin, C. (ed) Chinese Glass. Archaeological studies on the uses and social contest of glass artefacts from the Warring States to the Northern Song Menstruation (fifth century B.C. to 12th century A.D.). ISBN 8822251628

- ^ Kerr, R. and Woods, Northward. (2004) "Office XII: Ceramic applied science" pp. 474–477 in Science and Civilisation in China. Book five, Chemistry and Chemic Applied science. Cambridge University Press. ISBN 0521838339

- ^ An Jiayao (2002) "Polychrome and monochrome drinking glass of the Warring States and Han periods" pp. 45–46 in Braghin, C. (ed) Chinese Glass. Archaeological studies on the uses and social contest of glass artefacts from the Warring States to the Northern Vocal Period (fifth century B.C. to twelfth century A.D.). ISBN 8822251628.

- ^ Jenyns, R. (1981) Chinese Art 3: Textiles, Glass and Painting on Drinking glass. Phaidon Press

- ^ Whitehouse, David; Glass, Corning Museum of (May 2004). Roman Glass in the Corning Museum of Glass. Hudson Hills. ISBN9780872901551.

- ^ The Fine art Periodical. Virtue and Visitor. 1888.

- ^ The Glass Manufacture. Ashlee Publishing Company. 1920.

- ^ Fleming, S. J., 1999. Roman Glass; reflections on cultural change. Philadelphia, University of Pennsylvania Museum of Archaeology and Anthropology.

- ^ Stern, East. M. (1999). "Roman Glassblowing in a Cultural Context". American Journal of Archæology. 103 (three): 441–484. doi:x.2307/506970. JSTOR 506970.

- ^ Toner, J. P. (2009) Popular culture in ancient Rome. ISBN 0-7456-4310-viii. p. xix

- ^ Hassan, Ahmad Y, Assessment of Kitab al-Durra al-Maknuna Archived 2010-07-15 at the Wayback Machine, History of Scientific discipline and Engineering in Islam.

- ^ Hassan, Ahmad Y. The Industry of Coloured Glass Archived 2010-xi-16 at the Wayback Auto, History of Science and Technology in Islam.

- ^ Oliver, Roland, and Fagan, Brian Yard. Africa in the Iron Age, c500 B.C. to A.D. 1400. New York: Cambridge University Press, p. 187. ISBN 0-521-20598-0.

- ^ Donny L. Hamilton. "Glass Conservation". Conservation Research Laboratory, Texas A&M University. Retrieved 2007-03-21 .

- ^ Bayley, J. (2000). "Glass-working in Early Medieval England" pp. 137–142 in Toll, J. Glass in Britain and Ireland Advertizement 350–1100. London: British Museum Occasional newspaper 127. ISBN 0861591275

- ^ a b c d Evison, 5. I. (2000). "Glass vessels in England, 400–1100 CE" pp. 47–104 in Price, J. Glass in Britain and Ireland Advertisement 350–1100. London: British Museum Occasional paper 127. ISBN 0861591275

- ^ a b Heyworth, Yard. (1992) "Evidence for early medieval glass-working in n-western Europe" pp. 169–174 in S. Jennings and A. Vince (eds) Medieval Europe 1992: Book three Technology and Innovation. York: Medieval Europe 1992

- ^ Ecclesiastical: Of or relating to a church or to an established religion.

- ^ Harden, D. B. (1978). "Anglo-Saxon and later Medieval drinking glass in Britain: Some contempo developments" (PDF). Medieval Archaeology. 22: i–24. doi:10.1080/00766097.1978.11735405.

- ^ Bimson Thousand. and Freestone, I.C. (2000). "Analysis of some drinking glass from Anglo-Saxon Jewellery" pp. 137–142 in Price, J. Drinking glass in U.k. and Republic of ireland AD 350–1100. London: British Museum Occasional paper 127. ISBN 0861591275

- ^ Bimson, Grand. (1978) "Coloured glass and millefiori in the Sutton Hoo Ship Burial". In Annales du 7e congrès international d'etude historique du verre: Berlin, Leipzig, 15–21 August 1977: Liège: Editions du Secretariat Général.

- ^ Georg Agricola De Natura Fossilium, Textbook of Mineralogy, Chiliad.C. Bandy, J. Bandy, Mineralogical Society of America, 1955, p. 111 Department on Murano Glass, De Natura Fossilium. Retrieved 2007-09-12.

- ^ inc, Encyclopaedia Britannica (1992). The New Encyclopaedia Britannica. Encyclopaedia Britannica. ISBN9780852295533.

- ^ Newton, Roy M.; Sandra Davison (1989). Conservation of Glass. Butterworth – Heinemann Series in Conservation and Museology. London: Butterworths. ISBN0-408-10623-9.

- ^ MacLeod, Christine (1987). "Accident or Design? George Ravenscroft'southward Patent and the Invention of Lead-Crystal Glass". Applied science and Culture. 28 (4): 776–803. doi:10.2307/3105182. JSTOR 3105182.

- ^ Hurst-Vose, Ruth (1980). Glass. Collins Archaeology. London: Collins. ISBN0-00-211379-ane.

- ^ Encyclopædia Britannica 11th edition (1911)

- ^ Bontemps on Glassmaking: the Guide du Verrier of Georges Bontemps, translated by Michael Cable (2008). Society of Glass Engineering. ISBN 0900682604

- ^ Buch Polak, Ada (1975). Glass: its tradition and its makers . Putnam. p. 169. ISBN9780399115233.

- ^ "Chance Brothers and Co". Retrieved 2012-12-17 .

- ^ Practical Building Conservation: Glass and glazing. Ashgate Publishing. 2011. p. 468. ISBN9780754645573.

- ^ Pilkington, L. A. B. (1969). "Review Lecture. The Float Glass Process". Proceedings of the Regal Society of London. Series A, Mathematical and Physical Sciences. The Royal Society. 314 (1516): 1–25. Bibcode:1969RSPSA.314....1P. doi:10.1098/rspa.1969.0212. JSTOR 2416528. S2CID 109981215.

- ^ "Borosilikatglas BOROFLOAT®". SCHOTT AG.

- ^ Bickerstaff, Kenneth and Pilkington, Lionel A B U.S. Patent ii,911,759 "Manufacture of apartment drinking glass". Priority date Dec 10, 1953

Further reading [edit]

- Carboni, Stefano; Whitehouse, David (2001). Glass of the sultans . New York: The Metropolitan Museum of Fine art. ISBN0870999869.

Source: https://en.wikipedia.org/wiki/History_of_glass

0 Response to "Can You Take 1900 s Clear Glass That Is Darkened and Make It Clear Again"

Post a Comment